Aichelin Ges.m.b.H. in Modling/Austria is a member of the international AICHELIN Group is in business for over 150 years. In addition to the production and the after sales service of industrial furnaces for different industries, the AICHELIN Group is active in the field of induction heating, as well as the production of industrial gas burner systems, large size Bogie Hearth furnaces, Batch furnaces, Pusher furnaces and Mesh Belt furnaces. All these furnaces are equipped with advanced automation system.

AICHELIN, SAFED & BOSIO are technological leaders in this area with profound technical consulting competence for heat treatment furnaces and the necessary knowledge in process engineering. Mainly electrical and gas heated furnaces such as multi-purpose chamber, pusher type, conveyor belt, ring hearth, rotary hearth, bogie hearth, reheating and roller hearth furnaces are produced. Additionally, AICHELIN provides systems for cleaning of parts, protective gas generators and automation systems. Our after sales service provides spare parts and further customized services to our customers, such as reconstructions, trainings, etc.

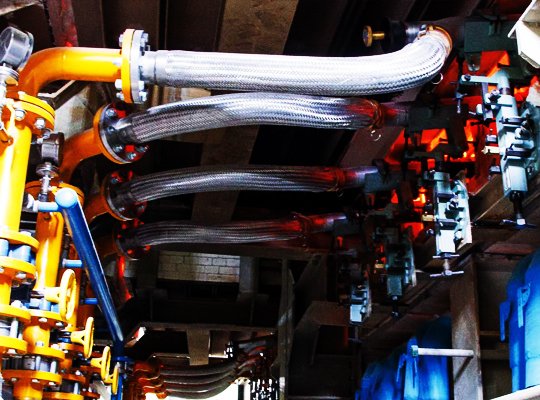

NOXMAT GmbH has its core competences in developing, engineering and manufacturing industrial gas burners and controllers. They are used in plants for preheating and heat treatment of metallic materials and non-ferrous metals. Further, these burners can be used in the ceramic, environmental and chemical industry.

The JVC combines the vast industrial heat treatment experience of the following companies.

RELIABILITY OF WORK

AICHELIN industrial furnaces are known all over the world for their top quality. Furnaces are designed, manufactured and sold from factories in Austria, China, and India. Our claim to offer the best solutions regarding technology, price, and economic efficiency makes AICHELIN a first-choice partner for the automobile, screws, and bearings industries as well as for manufacturers of precision and small bulk parts.

RELIABILITY OF WORK

AICHELIN industrial furnaces are known all over the world for their top quality. The furnaces are planned, manufactured and sold from sites in Austria, China, and India. Our claim to offer the best solutions regarding technology, price, and economic efficiency makes AICHELIN a first-choice partner for the automobile, screws, and bearings industries as well as for manufacturers of precision and small bulk parts.

TECHNOLOGY LEADER FOR THERMAL PROCESSING EQUIPMENT

The number one in the US. AFC HOLCROFT's sturdy and reliable industrial furnaces are a global success. The long-established American company offers a uniquely broad spectrum of skills and products; from simple furnaces to fully automatic heat treatment lines, from standard solutions to highly individual plants - with extensive after sales services, maintenance and spare parts inclusive. AFC-Holcroft has subsidiaries in China and Switzerland as well as a global network of partners in Australia, Brazil, China, India, Mexico, Poland, and Spain.

ADVANCED HEAT TREATMENT SOLUTIONS

The industrial furnace manufacturer from Slovenia is one of the leading providers of heat treatment plants in Central and Eastern Europe. BOSIO is a specialist of forged components. The company mainly supplies the steel production and processing industry with large chamber, bogie hearth, and shaft furnaces.

THE SPECIALIST FOR MESH BELT FURNACES

The long-established Swiss company SAFED joined the AICHELIN Group in 2007. The small bulk parts of SAFED cast-link belt furnaces are designed, constructed, and manufactured at the AICHELIN Mödling site near Vienna for precision. The SAFED sites in Delémont (Switzerland), Besançon (France), and Ludwigsburg (Germany) handle services, modifications, modernizations, and spare parts for SAFED furnace plants.

THE EXPERT FOR INDUSTRIAL COMBUSTION TECHNOLOGY

The design, construction, and manufacturing of industrial gas burner systems and their control units are the specialty of NOXMAT GmbH. Operators and Manufacturers of industrial furnace plants all over the world trust the reliability, performance, and efficiency of the NOXMAT burner systems.

PROVIDING BEST PERFORMANCE

As a global provider, AICHELIN’s extensive skills for servicing industrial furnaces are bundled in its own company with headquarters in Ludwigsburg, a subsidiary in Mödling, and the service company SAFED. More than 100 specialists offer extensive global services for AICHELIN, SAFED, and numerous other furnaces. The service portfolio is tailored exactly according to the requirements of plant operators and is being upscaled continuously since then. Global Services’ mission is to keep plant availability and productivity permanent and economically efficient.

THE AUSTEMPERING SPECIALIST

Atmosphere Heat Treating is the heat treatment specialist for continuous salt bath hardening.

THE AUSTEMPERING SPECIALIST

Atmosphere Heat Treating is the contract heat treatment specialist for continuous salt bath hardening.

Unitherm Group is a well-known brand in India for manufacturing of state-of-art heat treatment plants and supplying heat treatment services.

In a strategic partnership with the leading European furnace manufacturers, the company has strengthened its position as the largest heat treatment company in India with plants in West, North and South India.

The company is catering to the heat treatment requirements of engineering industries by offering a full range of heat treatment services as one stop supplier for variety of engineering products.

Aichelin Unitherm Heat Treatment Systems India Pvt. Ltd. is a leading heat treatment furnace manufacturer in India. It is a joint venture between Aichelin Group, Austria and Unitherm Engineers Ltd, India.

Products include gas and electrically heated furnaces such as Sealed Quench Furnace, Pusher type furnace, Mesh belt furnace, Ring hearth, Rotary hearth or Roller hearth furnaces. The company is a technological leader in this field with sound technical competence and necessary knowledge of process engineering.

After-sales service is an important part of the business and the company provides spare parts and services to our customers.

With 500+ furnace installations with leading OEMs and tier-1 automotive companies in India and Europe, the company is the leading brand for Sealed Quench Furnaces.

Unitherm Engineers Limited is the largest commercial heat treatment services provider in India.

With 3 plants at Pune (West India), Bangalore (South India) and Bhiwadi (North India), the company is strategically located close to automotive component manufacturers in major automotive hubs in India.

Heat treatment services provided include Carburizing, Case Hardening, Carbo-Nitriding, Gas Nitriding, Gas Nitro-Carburizing.

For more information, please visit www.unithermfurnaces.com

Indo-German Vacu Treat Pvt. Ltd. is the largest vacuum heat treatment services provider in India.

The company is a joint venture between Systherms, Germany and Unitherm Engineers Limited, India, with 3 plants located at Pune (West India), Banglore (South India) and Bhiwadi (North India). The company is strategically located close to tooling and component manufacturers in automotive hubs in India.

Vacuum heat treatment services provided include Vacuum Hardening, Solution Annealing, Plasma Nitriding, Vacuum Brazing, Vacuum Tempering, Stress Relieving etc.

For more information, please visit www.igvtvacutreat.com

Unitherm Nova Coating (UNC) is a pioneering joint venture between Unitherm Engineers Limited, India’s leading expert in commercial atmospheric heat treatment, and Nova Coating, Germany’s specialist in advanced surface coating technologies. This collaboration unites decades of expertise to deliver cutting-edge PVD coatings that enhance the performance, durability, and efficiency of tools and components across industries.

By combining advanced heat treatment and surface engineering, we provide high-performance coating solutions tailored to the unique needs of sectors such as automotive, aerospace, and manufacturing. Our coatings improve wear resistance, reduce friction, and optimize operational efficiency, helping businesses achieve superior productivity and cost savings.

At UNC, we are committed to innovation, precision, and quality, ensuring each coating meets the highest industry standards. With a focus on timely delivery and customized solutions, we work closely with our clients to enhance the reliability and longevity of their tools and components.

Partner with Unitherm Nova Coating for next-level industrial performance with state-of-the-art PVD coatings designed for excellence.

For more information, please visit

www.unc-india.com/